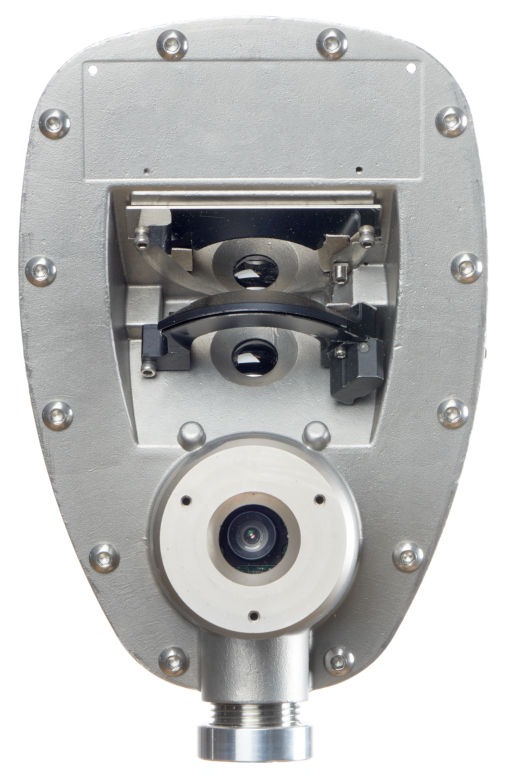

Draeger – MetCam Gas Camera

Description

The MetCam gas camera continuously monitors large areas for possible methane leaks. It makes the source and the intensity of the leaks visible. The camera can even detect small emissions.

Benefits

Visualize gas leaks

In the oil and gas industry, there are often spacious or labyrinthine plant areas that are difficult to reach or whose gas pipelines have many connections. Here, typical gas detection systems reach their limits. However, even under these conditions, an optical gas detection camera makes gas leaks visible in terms of their source and intensity. An ideal complement to your gas detection system for a more accurate and faster assessment of a potential hazard.

Increased safety and efficiency

The MetCam automatically monitors your facility around the clock. Unlike point detectors, the gas source need not be in the immediate proximity of the gas camera. It is sufficient if the source is in the field of view of the camera. The detection is thus independent of wind or similar influences. The MetCam detects gas leaks at an early stage and can warn you against them. This way, you can initiate countermeasures faster. This means more safety for your facility and greater efficiency.

Simple interpretation of the event and multipurpose use

The gas camera visualizes the gas cloud as a colored overlay on the black and white video image and independently quantifies the concentration. As a result, you simply interpret the event from a safe distance, for example, from your control room. You can also use the MetCam to measure emissions or as a surveillance camera with a color image.

Fewer false alarms, very low maintenance effort

The camera recognizes independently if the optics are dirty or covered, and alerts you accordingly. This reduces false alarms and ensures that your system is ready for use. In order to adapt to changing weather conditions, the MetCam regularly performs a self-calibration. A special maintenance or calibration is not necessary and the maintenance effort is low.

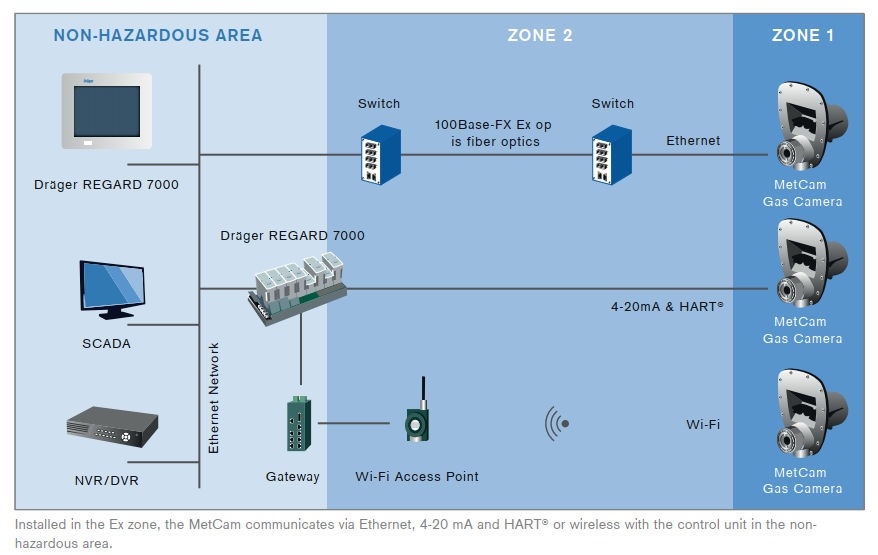

Various communication options

The MetCam offers various communication interfaces and supports corresponding protocols for data and video transmission. The analogue, 4 to 20 mA current interface in conjunction with HART®, can be used to transmit the alarms and the device status. The video transmission takes place via the Ethernet interface using LAN. There are two different operating modes available at the same time. One mode is the transmission of the black-and-white video with a color overlay of the detected gas cloud in the event of a leak. The second mode is a color video for area monitoring without showing the gas concentration.

Documented safety

All events and measured data are stored automatically, allowing you to understand and evaluate them later. You can also create emission logs with little effort.

Network Infrastructure with MetCam Gas Camera

MetCam Network Infrastructure

Technical Data

Camera Characteristics

| Measuring gas | Methane |

| Response time | < 10 seconds |

| Range | 10 to 50 m |

| Field of view | Horizontal 68° Vertical 28° |

| Lower detection threshold | > 60 g/h |

| Self-calibration | Every 3 to 5 minutes |

| Interval depending on the change in ambient temperature | |

| Communication/Protocol | Giga Ethernet |

| Modbus half-duplex | |

| ONVIF Protocol – Profile S | |

| HART® Protocol |

Electrical Data

| Output signals | 4-20 mA (stepped), HART® |

| RS 485 | RS-485 Modbus compatible interface |

| LAN | Giga Ethernet |

| Optional Wi-Fi | |

| Supply voltage | 24 VDC (16-30 VDC) |

| Power consumption | Max. 20 W |

Environmental Conditions

| Temperature range | Operation: -25 to +40 °C |

| Optional: -40 to +60 °C |

Housing

| Material | Stainless steel |

| Protection class | IP66 |

| Cable gland | 1 M25 or 3/4″ NPT |

| Weight | < 4.5 kg |

| Dimensions | 156 × 236 × 183 mm |

Approvals

| ATEX/ IECEx (pending) | Ex II 2G |

| Ex db ia IIB+H2 | |

| T6 Gb Tamb = -40°C to +60°C | |

| US & Canada (pending) | Class I, Division 1, Groups B, C, D, T6, -40°C ≤ Tamb ≤ 60°C |

HART® is a registered trademark of the HART® Communication Foundation

Solutions

Vector’s experienced engineers and technicians can provide solutions for your tough applications.

Services

Vector CAG can help schedule you for routine maintenance, installation, start up, commissioning, training and inspections.

Training

Vector University offers courses on all products to keep your processes running safely, optimally and cost effectively.