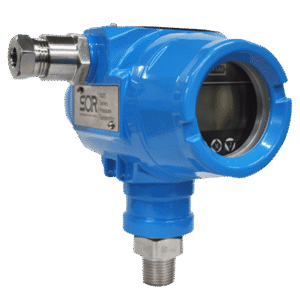

SOR Controls Group – Float Level Measurement

SOR level switches have earned a long-time reputation for their high quality, rugged construction and reliable performance under the most demanding applications. All float level switches are individually built with strict attention to detail to meet the exact specifications of your process.

Available as float level switches and displacer level switches, our product offering provides superior alarm and monitoring control for heavy industries such as power generation, refining, petrochemical and general manufacturing.

PRODUCT DESCRIPTION:

About Liquefied Gas Sampling Systems

This group of process liquids has a vapor pressure > 19 psia and will boil at atmospheric conditions. This requires that these samples be caught in cylinders to keep the composition and material phase identical to actual operating conditions for lab analysis.

The SENSOR Liquefied Gas Sampling System (LGSS) allows for collection of samples from light liquid hydrocarbon applications in a manner that is safe to both the operator and the environment. The sampling process ensures zero emissions, with no spills and zero Volatile Organic Compounds (VOC) emissions, while keeping sample contamination levels to a minimum.

Liquids are not compressible and therefore there needs to be a technique for ensuring a safe outage in the sample cylinder. The Liquefied Gas Sampling System (LGSS) allows an operator to visually verify cylinder outage and maximum fill density through our innovative sight glass system, ensuring compliance with regulatory requirement U.S. CFR49.

Typical closed loop cylinder sampling applications include; liquid methane, ethane, propane, butane, ISO butane, butene, pentene, acetylene, ethylene, propylene, butadiene, ethylene oxide, propylene oxide and xylene. These closed loop cylinder sampling systems are usually connected to a flare or vapor recovery system to allow for vaporization and depressurization of excess process captured in tubing and hoses.

Key Features

- Designed for placement into fast loop to ensure fresh representative sample is always present

- Cylinder clamp to correctly position and secure sample cylinder

- Robust double-ended shutoff quick-connect fittings; Swagelok QC4 and QTM2, Parker 60 series

- Ability to depressurize QC’s before removing cylinder from sample panel ensures closed loop for zero emission sampling

- Simple design, easy to use, single handle operation

- Panel mounted pressure gauge

- Operating Instruction Manual included

- Standard design conditions up to 1,400 psig and 180oF

Industries Served

- Refining

- Chemicals

- Petrochemicals

- Fractionation