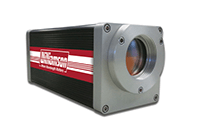

Williamson

Williamson is a family-owned manufacturer of exceptionally accurate infrared pyrometers for industrial applications. Williamson is passionate about helping customers solve challenging temperature measurement problems so that they can improve product quality, increase process efficiency, and control costs. We recognize that each application has its own unique challenges and for over 60 years, Williamson has developed customized solutions for the most demanding industrial applications.

Industries

Solutions

Vector’s experienced engineers and technicians can provide solutions for your tough applications.

Services

Vector CAG can help schedule you for routine maintenance, installation, start up, commissioning, training and inspections.

Training

Vector University offers courses on all products to keep your processes running safely, optimally and cost effectively.